描述

Which type of formwork is used for concrete?

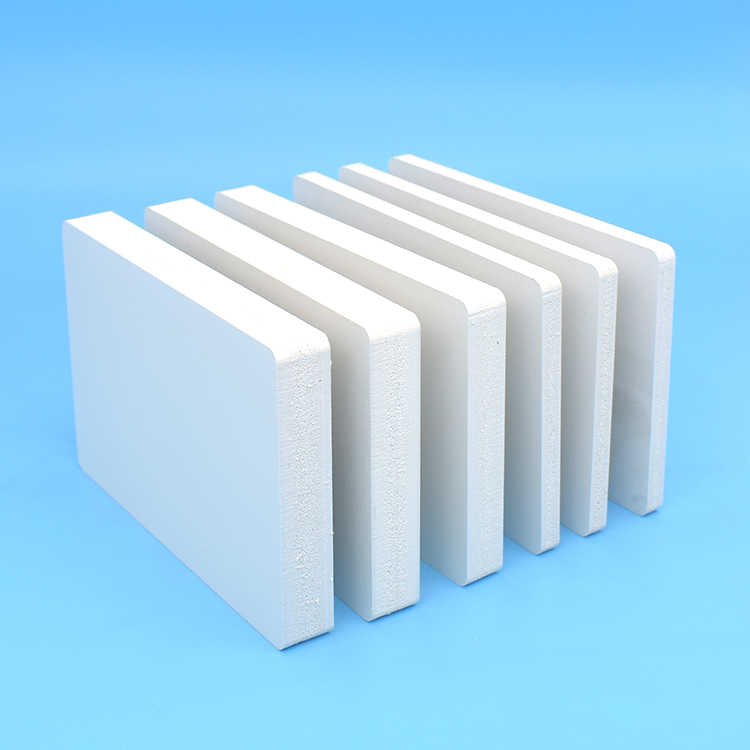

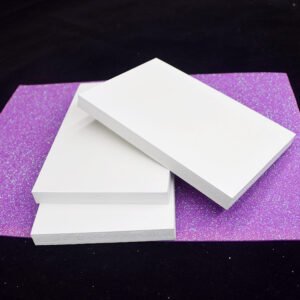

Today we are going to introduce a highly favored construction formwork – plastic concrete formwork. This kind of template is made of PVC plastic as raw material, through high temperature hot pressing process, can be recycled, with energy saving and environmental protection, economic and efficient, lightweight and practical characteristics, so it is widely used in the construction field. 2700*1250*21mm PVC concrete plastic formwork.

What tangible benefits you get by buying our formwork

We are professional plastic construction formwork factory, we use 19 years of production experience, as well as 10 years of export experience, we do return customers, one is a one-time sale!

Name | plastic concrete formwork |

THK | 5-30MM |

Color | white |

Certificates | ISO9001, SGS, CE |

Why Choose GreenPlastic’s Formwork?

1.No deformation at high temperature, no slurry leakage

Our new upgraded PVC building formwork has the property of no deformation at high temperature, which is not available in other plastic formwork and plywood. It can be used, stored and placed outdoors in any season without any protection, and will not shrink, bulge, crack or show any signs of deformation in temperatures ranging from -40°C to +75°C.

2. Simple structure and construction process

PVC plastic formwork has no cumbersome process, the same preparation, handling, installation and assembly as traditional plywood for walls, floor slabs, columns, staircases, tunnels, bridges, etc, bridges, etc. No changes to existing structures or construction techniques are required. No additional No additional training or special tools required.

3. Better and more durable than plywood

PVC plastic formwork can be reused ≥ 50 times in ordinary wooden structures and more times in high-quality metal structures. This means that the service life of 1 PVC plastic formwork is equivalent to the service life of 5~10 plywood formwork. Plywood formwork.

4. Less expensive and more environmentally friendly than plywood

PVC plastic formwork does not require the use of mold release agents or oils before or during concrete stripping. Therefore, it can be easily stripped by hand with just water and a mop, thus keeping the wall smooth and shiny without the need for secondary plastering. Moreover, PVC formwork will be recycled after the project is finished, so it will not pollute the environment.

5. More versatile than plywood

PVC plastic formwork has excellent bending strength and can be bent freely in round formwork structures. Even in winter, PVC plastic formwork retains its elasticity when bending and is resistant to damage at temperatures of up to -40°C.

评价

目前还没有评价